If you’ve ever visited a retail store and looked at a product’s price tag, you’ve likely come across a stock keeping unit (SKU), commonly referred to as a SKU number. A SKU number is an alphanumeric code that helps Retailers track inventory and is usually placed on a product’s price tag/sticker. It is used to identify the product for the retailer.

For business owners with physical inventory, SKU numbers are critical for managing inventory/tracking sales. We’re going to cover everything you need to know about SKU numbers: what they are, why they’re important, how to generate one plus additional advice and tips.

What is a SKU number?

A SKU (stock keeping unit) is a unique alphanumeric code that Retailers assign to products to make managing their inventory more efficient. Typically, SKU numbers are between eight and 12 characters long, and each character corresponds to a unique characteristic of the product it represents (like the item’s type, brand, style, or the department it belongs to) or something that uniquely identifies the product.

SKUs are also completely unique from one business to another. They’re unique to your business and the information they contain should reflect what your customers or vendors ask most frequently about the merchandise you carry. Different businesses use SKU numbers to track different things, depending on what type of products they sell.

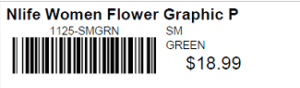

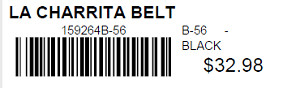

For example, a clothing store might need to create a unique SKU based off the primary vendor/supplier style number followed by the size and color.

Example would be style# 1125SMGRN where the first four digits represent the product’s style number, the next two represent the size, the following five represent its color (like GRN for green or BLK for black). Trying to keep up with these outside the system using spread sheets can be tedious and prone to human error.

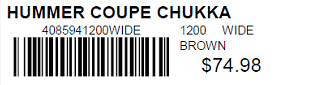

In Realtime pos the system automatically combines the style number, size and color and provides a combined unique SKU using the system stored size and color templates. The maximum of 5 characters is used for each style, size1, size2, color combinations. These fields are alpha numeric so you can use letters and numbers. We would recommend not to use “0” or “O” for the starting character as the Barcode is generated using the SKU field may not be readable.

Footwear – in footwear you may need to further classify the SKU by also using Size 2, you can combine Style, size1, size2 and color to create unique SKU numbers for different style shoes/footwear.

How are SKU numbers used?

Retailers use SKU numbers to track their inventory and sales, but they can also lend to forecasting future sales and demand, and personalizing which products are recommended to customers in-store and online.

A proper Department Structure is critical in grouping your inventory Items for reporting (sales, promotions and inventory on hand) Retail POS Department Structure – A properly defined structure will pay dividends or cause confusion

Accurately track inventory

Since SKUs are used to track a product’s characteristics, they can also be used to track inventory overall. For instance, a merchant can use SKU numbers to track a product’s availability and overall stock levels across multiple retail stores.

By having up-to-date inventory levels, retailers can order more of a product before running out of stock. In Realtime POS, retailers can take their inventory management one step further and set reorder points. When inventory levels of a product reach its reorder point (the minimum amount you want in stock at all times), that product, and the quantity you need to order, is automatically added to your Reorder List report and ready to be included in your next purchase order.

By having a combination of a properly defined department structure and SKU Definitions (size1, size2, color) the data view would be complete and no need to embed department, category, subcategory, brand and any other data into the SKU definitions as they were all defined in the item creation process in Realtime POS.

Forecast sales

By accurately tracking inventory levels by SKU numbers (OH-on hand, OO-On Order, MIN-Minimum OH, MAX-Maximum OH), these metrics will help retailers forecast sales and anticipate what products they need to stock up on to fulfill the demand from customers and avoid out-of-stock.

Recommend relevant products

By tracking products using SKU numbers that represent a product’s characteristics (type, size, color, etc), retailers are equipping their sales reps with an invaluable tool: information.

If the product a customer wants is out of stock, sales associates can explore alternative products with similar characteristics based on its SKU number—those are items the customer may also like.

Increase customer satisfaction

Since SKU numbers help retailers anticipate which products they need to reorder (and when to reorder them), they’re more likely to have the products a customer wants in stock.

By minimizing the amount of out-of-stock items, retailers can establish themselves as a reliable source that customers can count on to have the products they need.